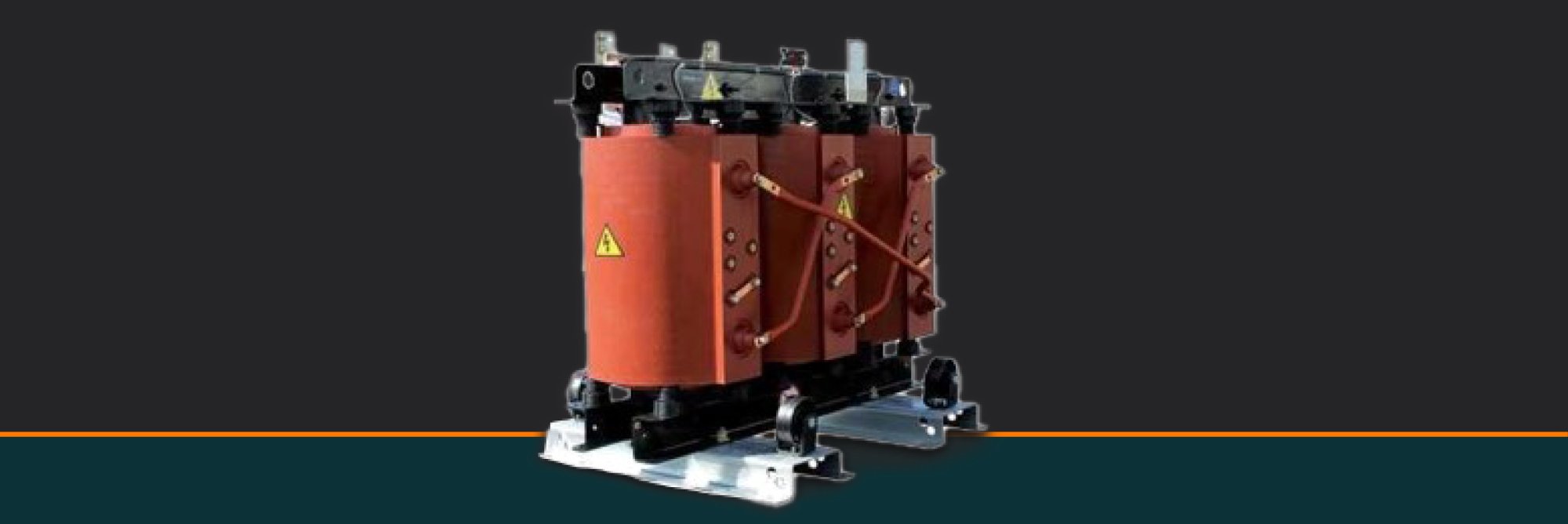

Transformers

Dry Type Transformer

Dry-Type Transformers: Enhancing Safety, Efficiency, and Reliability

Introduction to Dry-Type Transformers:

Dry-type transformers are an integral part of electrical distribution systems, providing efficient and reliable voltage transformation in various applications. Unlike traditional oil-filled transformers, dry-type transformers utilize air or solid insulation materials, making them environmentally friendly and suitable for indoor installations. Their versatility, safety features, and high performance make them a preferred choice for a wide range of industries and infrastructure projects.

Advantages of Dry-Type Transformers:

- Environmental Friendliness: Dry-type transformers eliminate the need for liquid dielectric, reducing the risk of environmental contamination from oil leaks or spills. This makes them ideal for installations where environmental protection is a priority.

- Safety: With no flammable liquid insulation, dry-type transformers offer enhanced safety features, reducing the risk of fire hazards. They are often preferred in buildings, tunnels, and underground installations where fire safety is critical.

- Minimal Maintenance: Dry-type transformers require minimal maintenance compared to oil-filled transformers, as there is no need for regular oil testing, filtering, or refilling. This results in lower operating costs and reduced downtime for maintenance activities.

- Compact Design: Dry-type transformers are typically more compact and lightweight than their oil-filled counterparts, making them easier to transport, install, and integrate into existing electrical systems. Their compact design also allows for flexible installation in space-constrained environments.

- High Insulation Properties: Dry-type transformers utilize air or solid insulation materials with high dielectric strength, providing excellent insulation properties and ensuring reliable operation even in harsh environmental conditions.

Applications of Dry-Type Transformers:

- Commercial Buildings: Dry-type transformers are commonly used in commercial buildings, including offices, hospitals, schools, and shopping centers, where safety, reliability, and environmental considerations are paramount.

- Industrial Facilities: In industrial settings such as manufacturing plants, chemical facilities, and refineries, dry-type transformers play a crucial role in providing efficient power distribution while meeting stringent safety and environmental regulations.

- Infrastructure Projects: Dry-type transformers are widely used in infrastructure projects such as transportation systems, tunnels, and underground installations, where fire safety and environmental protection are essential considerations.

- Renewable Energy Integration: With the growing adoption of renewable energy sources such as solar and wind power, dry-type transformers are increasingly used in renewable energy installations to step up or step down voltage levels and facilitate grid integration.

- Data Centers: Dry-type transformers are an integral part of data center infrastructure, providing reliable power distribution to critical IT equipment while ensuring safety and environmental compliance.

Design and Construction of Dry-Type Transformers:

- Core and Windings: Dry-type transformers consist of a core made of high-permeability magnetic materials such as laminated silicon steel, surrounded by primary and secondary windings made of copper or aluminum conductors.

- Insulation System: The insulation system of dry-type transformers typically includes air or solid insulation materials with high dielectric strength, providing excellent insulation properties and ensuring reliable operation.

- Enclosure: Dry-type transformers are housed in enclosures made of non-combustible materials such as steel or aluminum, providing protection against environmental factors such as moisture, dust, and physical damage.

- Cooling System: Dry-type transformers may incorporate natural air cooling or forced air cooling systems to dissipate heat generated during operation, ensuring optimal temperature regulation and efficient performance.

Some of the main advantages of dry type transformers are:

- Dry transformers enhance safety by eliminating flammable or toxic liquids, reducing the risk of leaks or fires.

- They are maintenance-free and pollution-free because they do not require any oil changes, oil tests, oil spills cleanup, or special disposal methods.

- They are easy to install because they do not require any vaults or special foundations. They can be placed close to the load to reduce the need for long and costly low voltage cables.

- They are environmentally friendly because they do not emit any harmful gases or contribute to the greenhouse effect.

- These transformers excellently handle overloads due to their superior heat dissipation and thermal endurance compared to oil-filled types.

- They have reduced costs on civil installation works and fire protection systems because they do not need any oil containment pits, fire walls, fire extinguishers, or sprinklers.

- They have excellent performance in the case of seismic events because they have a rigid structure that can withstand vibrations and shocks.

- They have no fire hazard because they have self-extinguishing properties and do not produce any smoke or flames in case of faults.

- They have excellent resistance to short-circuit currents because they have low impedance and high mechanical strength.

- They are long-lasting due to low thermal and dielectric heating because they have high-quality insulation materials that can withstand high temperatures without degrading.

- They are suited for damp and contaminated areas because they have high moisture ingress protection and corrosion resistance.